1. 案例

一个温度为300℃的铜环和一个温度为200℃的铁环,放置到22℃的水中进行淬火。水桶为铁质的圆形。分析中忽略水的流动。

材料参数

| 热性能 | 铜 | 铁 | 水 |

|---|---|---|---|

| 导热系数(W/(m℃) | 383 | 70 | 0.61 |

| 密度(kg/m3 | 8889 | 7833 | 996 |

| 比热容(J/(kg.℃) | 390 | 448 | 4185 |

因为忽略了水的流动,故可将水看为一种材料,直接进行分析

2. APDL分析

finish

/clear

!==============第一步:进行稳态二维轴对称分析===============================

/filname,quench

/prep7

et,1,plane55 ! 选择单元类型

keyopt,1,3,1 ! 设置为轴对称分析

! 定义材料热性能参数

mp,kxx,1,383

mp,dens,1,8889

mp,c,1,390 ! 定义铜的热物理性能参数

mp,kxx,2,70

mp,dens,2,7837

mp,c,2,448 ! 定义铁的热物理性能参数

mp,kxx,3,0.61

mp,dens,3,996

mp,c,3,4185 ! 定义水的热物理性能参数

rectng,0,0.08,0,0.01

rectng,0.08,0.1,0,0.01

rectng,0.1,0.12,0,0.01

rectng,0.12,0.14,0,0.01

rectng,0.14,0.15,0,0.01

rectng,0.14,0.15,0.01,0.055

rectng,0.14,0.15,0.055,0.1

rectng,0.14,0.15,0.1,0.15 ! 建立铁箱矩形

rectng,0.08,0.1,0.01,0.055

rectng,0.1,0.12,0.01,0.055 ! 建立铜环

rectng,0.08,0.1,0.055,0.1 ! 建立铁环

rectng,0,0.08,0.01,0.055

rectng,0.12,0.14,0.01,0.055

rectng,0,0.08,0.055,0.1

rectng,0.10,0.12,0.055,0.1

rectng,0.12,0.14,0.055,0.1

rectng,0,0.08,0.1,0.15

rectng,0.08,0.1,0.1,0.15

rectng,0.10,0.12,0.1,0.15

rectng,0.12,0.14,0.1,0.15 ! 建立水几何模型

aglue,all ! 粘接各矩形

esize,0.003,0, ! 定义单元划分尺寸

asel,s,,,1,21,20

asel,a,,,23,29,1

aatt,2,1,1 ! 附于铁箱和铁环的材料属性

asel,s,,,30,33,3

aatt,1,1,1 ! 附于铜环的材料属性

asel,s,,,31,32,1

asel,a,,,34,39,1

asel,a,,,22

aatt,3,1,1 ! 附于水的材料属性

allsel,all

mshkey,2 ! 定义映射单元划分类型

amesh,all ! 划分单元

asel,s,,,1,21,20

asel,a,,,23,28,1

asel,a,,,31,32,1

asel,a,,,34,39,1

asel,a,,,22

nsla,,1

d,all,temp,20 ! 施加铁箱和水的温度约束条件

asel,s,,,30,33,3

nsla,,1

d,all,temp,300 ! 施加铜环的温度约束条件

asel,s,,,29

nsla,,1

d,all,temp,200 ! 施加铁环的温度约束条件

allsel,all

/solu

antype,trans ! 设定为瞬态分析

timint,off ! 关掉时间积分, 即设定为稳态分析

time,0.01 ! 设定只有一个子步的时间很小的载荷步

deltim,0.01 ! 设定求解时间子步

solve ! 求解

!==============第二步:进行瞬态二维轴对称分析===============================

time,3600 ! 设定求解时间

timint,on ! 打开时间积分

deltim,26,2,200 ! 设置时间步长,最大及最小时间步长

autots,on ! 打开自动时间步长

ddelet,all,temp ! 删除稳态分析中定义的节点温度

outres,all,1 ! 将每个子步的值写入数据库文件

solve ! 求解

finish

/post1

plnsol,temp,,0

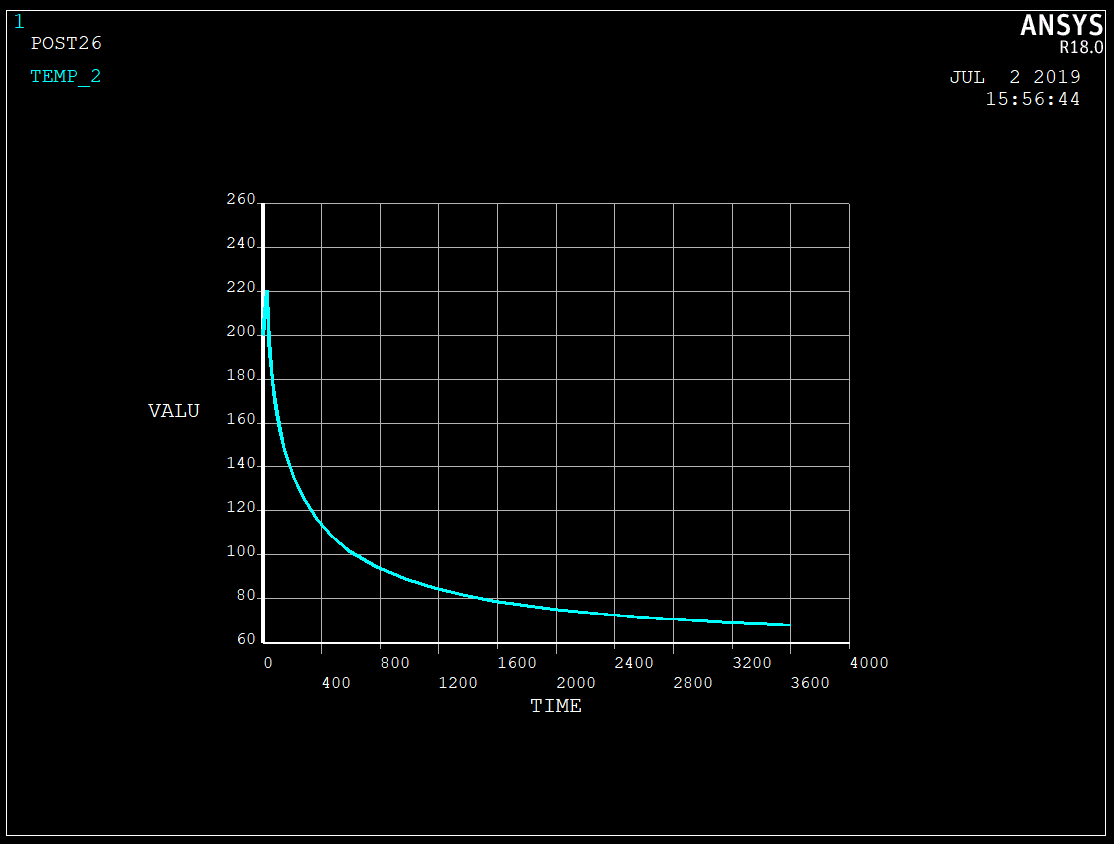

样件上的某点随时间变化的曲线