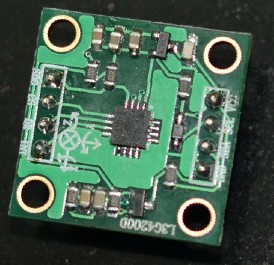

L3G4200D陀螺仪有点贵,好像要130左右,我买了散件回来自己焊接的,居然一次焊成功了,以前重来没焊过贴片工艺的板子,L3G4200D芯片太小了,不用镊子都拿不出,回想一下焊接过程还真的是很惊险刺激。来张焊好的作品:

其实这个板子和一个一元硬币差不多大,焊接手法还不错吧,哈。。

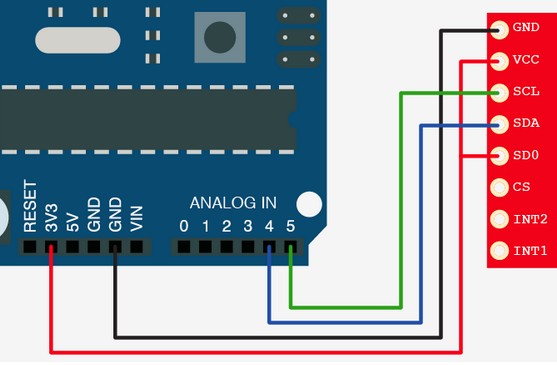

和ANDRIOD接线方式如下:

测试代码:

#include <Wire.h>

#define CTRL_REG1 0x20

#define CTRL_REG2 0x21

#define CTRL_REG3 0x22

#define CTRL_REG4 0x23

#define CTRL_REG5 0x24

int L3G4200D_Address = 105; //I2C address of the L3G4200D

int x;

int y;

int z;

void setup(){

Wire.begin();

Serial.begin(9600);

Serial.println("starting up L3G4200D");

setupL3G4200D(2000); // Configure L3G4200 - 250, 500 or 2000 deg/sec

delay(1500); //wait for the sensor to be ready

}

void loop(){

getGyroValues(); // This will update x, y, and z with new values

Serial.print("X:");

Serial.print(x);

Serial.print(" Y:");

Serial.print(y);

Serial.print(" Z:");

Serial.println(z);

delay(100); //Just here to slow down the serial to make it more readable

}

void getGyroValues(){

byte xMSB = readRegister(L3G4200D_Address, 0x29);

byte xLSB = readRegister(L3G4200D_Address, 0x28);

x = ((xMSB << 8) | xLSB);

byte yMSB = readRegister(L3G4200D_Address, 0x2B);

byte yLSB = readRegister(L3G4200D_Address, 0x2A);

y = ((yMSB << 8) | yLSB);

byte zMSB = readRegister(L3G4200D_Address, 0x2D);

byte zLSB = readRegister(L3G4200D_Address, 0x2C);

z = ((zMSB << 8) | zLSB);

}

int setupL3G4200D(int scale){

//From Jim Lindblom of Sparkfun's code

// Enable x, y, z and turn off power down:

writeRegister(L3G4200D_Address, CTRL_REG1, 0b00001111);

// If you'd like to adjust/use the HPF, you can edit the line below to configure CTRL_REG2:

writeRegister(L3G4200D_Address, CTRL_REG2, 0b00000000);

// Configure CTRL_REG3 to generate data ready interrupt on INT2

// No interrupts used on INT1, if you'd like to configure INT1

// or INT2 otherwise, consult the datasheet:

writeRegister(L3G4200D_Address, CTRL_REG3, 0b00001000);

// CTRL_REG4 controls the full-scale range, among other things:

if(scale == 250){

writeRegister(L3G4200D_Address, CTRL_REG4, 0b00000000);

}else if(scale == 500){

writeRegister(L3G4200D_Address, CTRL_REG4, 0b00010000);

}else{

writeRegister(L3G4200D_Address, CTRL_REG4, 0b00110000);

}

// CTRL_REG5 controls high-pass filtering of outputs, use it

// if you'd like:

writeRegister(L3G4200D_Address, CTRL_REG5, 0b00000000);

}

void writeRegister(int deviceAddress, byte address, byte val) {

Wire.beginTransmission(deviceAddress); // start transmission to device

Wire.write(address); // send register address

Wire.write(val); // send value to write

Wire.endTransmission(); // end transmission

}

int readRegister(int deviceAddress, byte address){

int v;

Wire.beginTransmission(deviceAddress);

Wire.write(address); // register to read

Wire.endTransmission();

Wire.requestFrom(deviceAddress, 1); // read a byte

while(!Wire.available()) {

// waiting

}

v = Wire.read();

return v;

#define CTRL_REG1 0x20

#define CTRL_REG2 0x21

#define CTRL_REG3 0x22

#define CTRL_REG4 0x23

#define CTRL_REG5 0x24

int L3G4200D_Address = 105; //I2C address of the L3G4200D

int x;

int y;

int z;

void setup(){

Wire.begin();

Serial.begin(9600);

Serial.println("starting up L3G4200D");

setupL3G4200D(2000); // Configure L3G4200 - 250, 500 or 2000 deg/sec

delay(1500); //wait for the sensor to be ready

}

void loop(){

getGyroValues(); // This will update x, y, and z with new values

Serial.print("X:");

Serial.print(x);

Serial.print(" Y:");

Serial.print(y);

Serial.print(" Z:");

Serial.println(z);

delay(100); //Just here to slow down the serial to make it more readable

}

void getGyroValues(){

byte xMSB = readRegister(L3G4200D_Address, 0x29);

byte xLSB = readRegister(L3G4200D_Address, 0x28);

x = ((xMSB << 8) | xLSB);

byte yMSB = readRegister(L3G4200D_Address, 0x2B);

byte yLSB = readRegister(L3G4200D_Address, 0x2A);

y = ((yMSB << 8) | yLSB);

byte zMSB = readRegister(L3G4200D_Address, 0x2D);

byte zLSB = readRegister(L3G4200D_Address, 0x2C);

z = ((zMSB << 8) | zLSB);

}

int setupL3G4200D(int scale){

//From Jim Lindblom of Sparkfun's code

// Enable x, y, z and turn off power down:

writeRegister(L3G4200D_Address, CTRL_REG1, 0b00001111);

// If you'd like to adjust/use the HPF, you can edit the line below to configure CTRL_REG2:

writeRegister(L3G4200D_Address, CTRL_REG2, 0b00000000);

// Configure CTRL_REG3 to generate data ready interrupt on INT2

// No interrupts used on INT1, if you'd like to configure INT1

// or INT2 otherwise, consult the datasheet:

writeRegister(L3G4200D_Address, CTRL_REG3, 0b00001000);

// CTRL_REG4 controls the full-scale range, among other things:

if(scale == 250){

writeRegister(L3G4200D_Address, CTRL_REG4, 0b00000000);

}else if(scale == 500){

writeRegister(L3G4200D_Address, CTRL_REG4, 0b00010000);

}else{

writeRegister(L3G4200D_Address, CTRL_REG4, 0b00110000);

}

// CTRL_REG5 controls high-pass filtering of outputs, use it

// if you'd like:

writeRegister(L3G4200D_Address, CTRL_REG5, 0b00000000);

}

void writeRegister(int deviceAddress, byte address, byte val) {

Wire.beginTransmission(deviceAddress); // start transmission to device

Wire.write(address); // send register address

Wire.write(val); // send value to write

Wire.endTransmission(); // end transmission

}

int readRegister(int deviceAddress, byte address){

int v;

Wire.beginTransmission(deviceAddress);

Wire.write(address); // register to read

Wire.endTransmission();

Wire.requestFrom(deviceAddress, 1); // read a byte

while(!Wire.available()) {

// waiting

}

v = Wire.read();

return v;

}

upload到andriod就可以通过COM口查看陀螺仪的测量结果了:

starting up L3G4200D

X:5 Y:0 Z:6

X:6 Y:1 Z:6

X:3 Y:1 Z:6

X:0 Y:2 Z:7

X:6 Y:0 Z:6

X:3 Y:0 Z:10

X:2 Y:0 Z:9

X:1 Y:0 Z:7

X:3 Y:3 Z:6

X:1 Y:0 Z:9

X:4 Y:1 Z:9

X:9 Y:1 Z:8

X:3 Y:1 Z:7

X:6 Y:1 Z:6

X:4 Y:1 Z:11

X:8 Y:0 Z:10

X:8 Y:0 Z:8

X:6 Y:1 Z:11

X:6 Y:1 Z:8

X:8 Y:1 Z:11

X:2 Y:0 Z:7

X:1 Y:1 Z:10

X:6 Y:1 Z:4

X:7 Y:1 Z:9

X:5 Y:2 Z:9

X:4 Y:9 Z:-5

X:14 Y:-5 Z:30

X:4 Y:0 Z:7

X:2 Y:0 Z:0

X:8 Y:0 Z:8

X:4 Y:0 Z:12

X:3 Y:1 Z:9

X:5 Y:2 Z:9

X:5 Y:0 Z:6

X:6 Y:1 Z:6

X:3 Y:1 Z:6

X:0 Y:2 Z:7

X:6 Y:0 Z:6

X:3 Y:0 Z:10

X:2 Y:0 Z:9

X:1 Y:0 Z:7

X:3 Y:3 Z:6

X:1 Y:0 Z:9

X:4 Y:1 Z:9

X:9 Y:1 Z:8

X:3 Y:1 Z:7

X:6 Y:1 Z:6

X:4 Y:1 Z:11

X:8 Y:0 Z:10

X:8 Y:0 Z:8

X:6 Y:1 Z:11

X:6 Y:1 Z:8

X:8 Y:1 Z:11

X:2 Y:0 Z:7

X:1 Y:1 Z:10

X:6 Y:1 Z:4

X:7 Y:1 Z:9

X:5 Y:2 Z:9

X:4 Y:9 Z:-5

X:14 Y:-5 Z:30

X:4 Y:0 Z:7

X:2 Y:0 Z:0

X:8 Y:0 Z:8

X:4 Y:0 Z:12

X:3 Y:1 Z:9

X:5 Y:2 Z:9

X:5 Y:0 Z:6

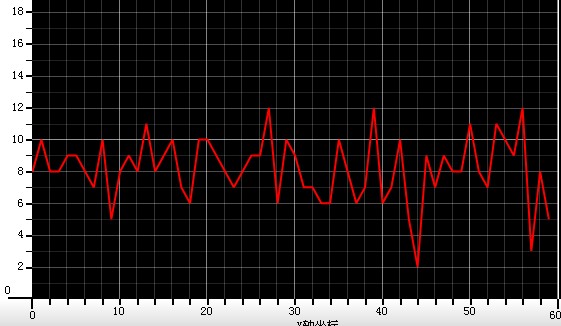

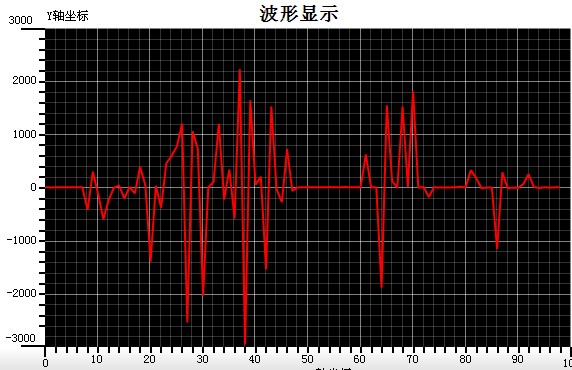

从结果看陀螺仪静止状态下数据还是有点跳动,这样就需要滤波,我准备配合加速度传感器利用卡尔曼滤波的方法来实现,目前尚在测试过程中。

下面是陀螺仪静止放在桌面上的Z轴角速度波形图:

陀螺仪运动中:

陀螺仪数据处理

陀螺仪的直接输出值是相对灵敏轴的角速率,角速率对时间积分即可得到围绕灵敏轴旋转过的角度值。由于系统采用微控制器循环采样程序获取陀螺仪角速率信息,即每隔一段很短的时间采样一次,所以采用累加的方法实现积分的功能来计算角度值:

公式中angle n为陀螺仪采样到第n次的角度值;angle (n-1)为陀螺仪第n-1次采样时的角度值;gyro n 为陀螺仪的第n次采样得到的瞬时角速率值;dt为主运行一遍所用时间。可见,用陀螺仪输出值积分计算角度,要求处理器运算速度足够快,采样程序应尽量简练,程序循环一遍所用时间dt越小,采样频率越高,最后积分得到的角度值才能越精确。

陀螺仪是用来测量角速度信号的,通过对角速度积分,能得到角度值。但由于温度变化、摩擦力和不稳定力矩等因素,陀螺仪会产成漂移误差。而无论多么小的常值漂移通过积分都会得到无限大的角度误差。因而,也不能单独使用陀螺仪作为本机器人倾角传感器。